Precision, Accountability, and Eco-Conscious Practices at Every Step.

Our Commitment to Excellence

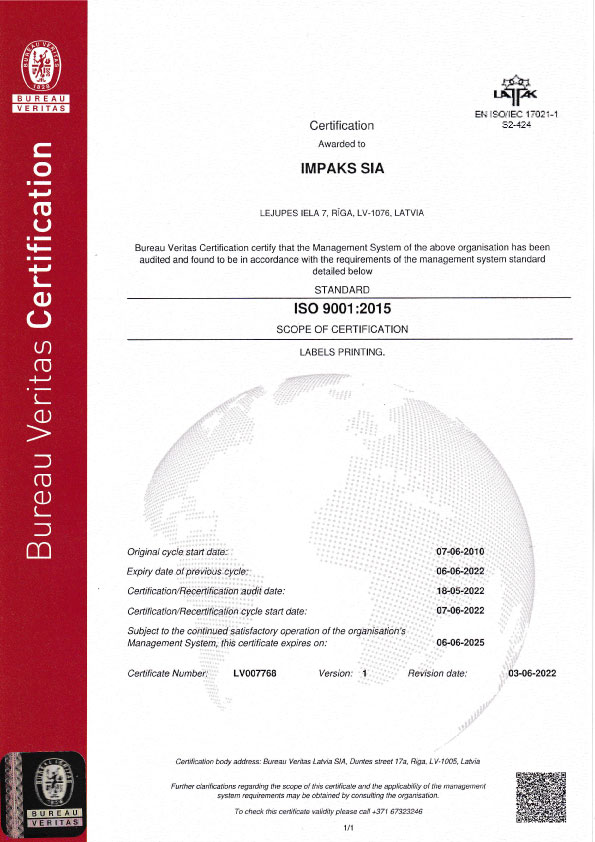

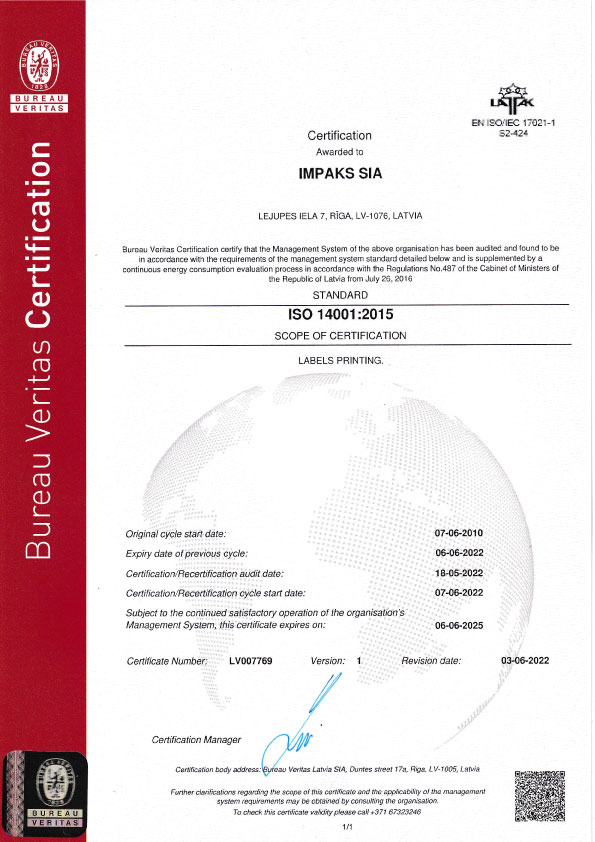

For over a decade, we have been certified under ISO 9001 (Quality Management System) and ISO 14001 (Environmental Management System). These certifications reflect our dedication to maintaining the highest quality standards in our production processes while ensuring a sustainable approach to our operations.

ISO 9001 Certification: This standard demonstrates our commitment to consistently delivering products that meet customer and regulatory requirements. Our robust quality management system ensures that every label we produce is crafted with precision and attention to detail, minimizing errors and maximizing customer satisfaction.

ISO 14001 Certification: Our environmental management system emphasizes our responsibility to reduce our ecological footprint. We prioritize sustainable practices in our production processes, using eco-friendly materials and methods that minimize waste and energy consumption. This commitment not only benefits our planet but also aligns with the values of environmentally conscious brands.

At IMPAKS our quality control system is meticulously established, ensuring that every stage of label production undergoes multi-tiered oversight. From the moment an order is placed to the final product, our processes are designed to minimize the potential for errors.

- In our colour laboratory, we utilize the InkFormulation program along with a spectrophotometer to create precise paint formulations. This technology allows us to achieve any desired shade and accurately replicate colours as needed. Each formulation is securely stored in our ink mixing station for consistency in future productions.

- Clients are invited to review the first print, where a template is created based on their specifications. Subsequent printing adheres strictly to established standards, with all verification results archived for reference. Cuts from the last two production runs of each label are also kept in our archive for quality assurance. As a proud member of FINAT, the global association of self-adhesive label manufacturers, we adhere to rigorous quality control methods. All materials undergo 100% inspection according to FINAT standards (FTM 8, FTM 9) and selective checks (FTM 1 and 2). Labels are randomly tested for abrasion resistance using the RUB-RT-01 Labthink tester, in compliance with ASTM D5264 and TAPPI T380 standards.

- We prioritize the security of our clients’ designs and layouts, storing all files on secure servers with regular backups. Our independent servers are located in different areas to safeguard against data loss due to unforeseen events.

- To protect our clients from counterfeit products, we ensure that only high-quality labels leave our facility, accompanied by an invoice and quality certificate. All test rolls, paint samples, and any rejected materials are responsibly destroyed and recycled.

- Our automated order management system not only streamlines order placement but also stores comprehensive data on production processes. Each order is assigned a unique identifier, optimizing efficiency for future orders. Additionally, we retain samples from each roll of the last two production runs for five years, ensuring traceability and accountability.